.png)

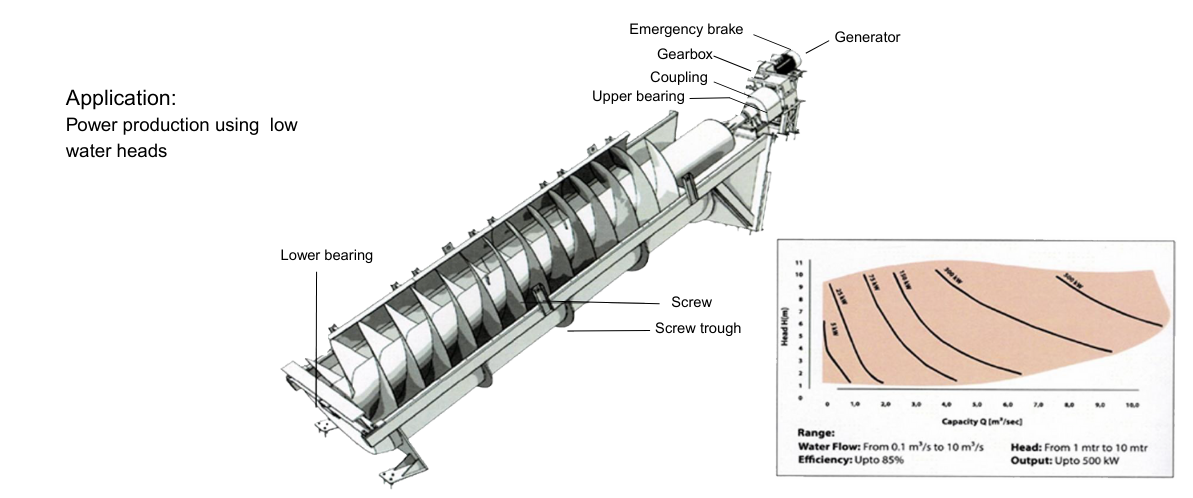

Water flows down by gravity through the screw turbine and this initiates its rotation. This rotation is transmitted to the gearbox and subsequently to generator with increased rpm to produce electricity. The inlet channel has a manual coarse screen to hold back bigger foreign floating materials coming with water and an emergency gate for the isolation of flow during maintenance.

Hydropower Screw

Operating Principle:

Operating Principle:

The water flows down through the screw and this initiates its rotation. This rotation is transmitted to the gear box and subsequently to generator with increased rpm to produce electricity. The inlet channel has a manual coarse screen to hold back bigger foreign floating materials coming with the water and an emergency gate for isolation of flow during maintenance.

Power calculation general thumb rule:

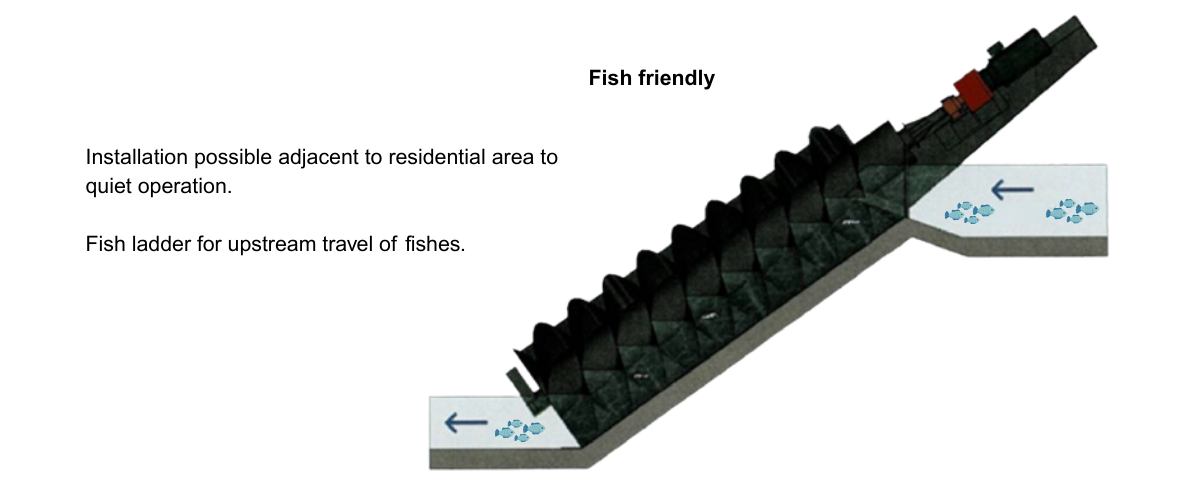

Quiet operation

The noise specific Rehart screw design & workmanship ensures smooth running & quiet operations. As a result fast project installation/ commissioning with lesser inconvenience to nearby community/ residents becomes possible.

Fast installation

Whether as a compact unit, semi-compact or steel though type, every Hydropower Screw system is delivered ready made. This enables installations within days of receipt of equipment.

Negligible operational cost

The sophisticated yet simple to use design needs no operating personnel. Monitoring is carried out via computers and monitoring data could be availed via text messages & emails. This result into negligible cost of its operation.

Low maintenance

Rigid design, low rotational speed and patented bearing system, ensures low product maintenance and breakdowns.

High reliability

All parts are manufactured to high quality standards. This ensures reliable generation of electricity and long life of equipment.

Types of Models/ Series

SERIES CR : Compact type: System completely factory assembled. All Components have been integrated. The Trough is designed as Tube. Suitable for low and medium volumes. Output unit under weather protection cover housing not required.

SERIES SH: Steel trough for casting: The trough is fastened at the precast structure and then with concrete. Practical mechanical engineering, high expenditure for hydraulic engineering.

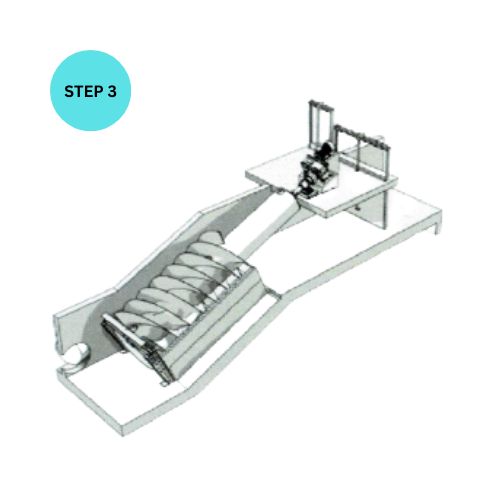

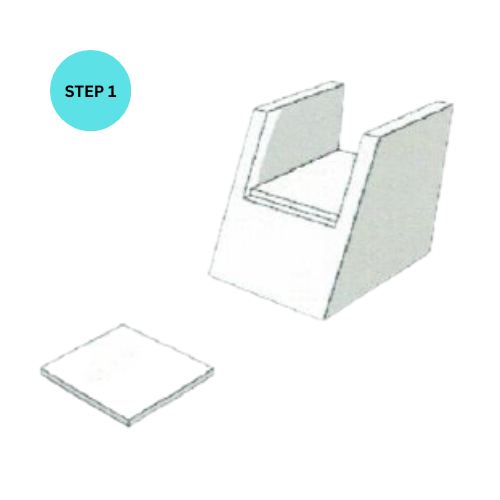

Assembly

Assembly of Hydropower screw series SH

.png)

.png)

.png)